Compressed Air System

June 14, 2025

Develop an Efficient Compressed Air System: A Four-Part Guide

Compressed air is one of the most essential and energy-intensive utilities in industrial facilities. An inefficient compressed air system can lead to wasted energy, increased operational costs, and unexpected downtime. For plant managers and engineers, developing a well-integrated and high-efficiency system requires careful planning and management across four critical areas: Generation, Treatment, Distribution, and Usage.

1. Compressed Air Generation: Start with Smart Sizing

The efficiency of your compressed air system begins at the compressor. Over-sizing or under-sizing the air compressor can lead to energy waste or insufficient supply. Best practices include :

- Accurately assess demand: Understand your plant's actual air demand

profile by analysing usage trends and peak loads.

- Choose the right generation pressure: Base the generation pressure

calculation on actual pressure required at demand point while accounting

for expected pressure drops between point of generation and point of

utilization.

- Choose the right compressor type: Centrifugal compressors for heavy

continuous demand, Rotary screw compressors for continuous but smaller

demands, while reciprocating compressors are better for intermittent

loads,

- Optimize load/unload cycles: Variable speed drive (VSD) compressors

can adjust to fluctuations in demand, reducing energy consumption.

- Install multiple compressors: A modular setup allows greater

flexibility and redundancy during maintenance.

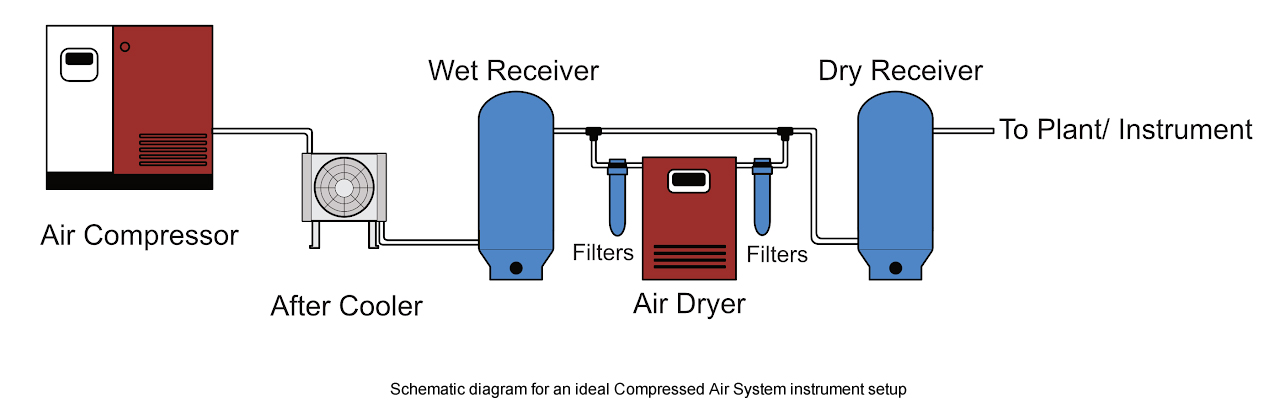

2. Compressed Air Treatment: Protect the System and Improve Quality

Untreated compressed air can carry moisture, oil, and particulates that damage equipment and affect product quality. Efficient air treatment is essential. Key components include :

- Air Dryers: Refrigerated dryers suit general applications; desiccant

dryers are used for extremely dry air requirements.

- After coolers: Remove bulk water right after compression.

- Filters: Install particulate, coalescing, and activated carbon

filters in stages to remove solid contaminants, oil and oil vapours.

- Wet and Dry receiver tanks: Wet receivers help reduce moisture before

the dryer; dry receivers provide stable supply after drying.

3. Compressed Air Distribution: Design for Minimal Losses

Once air is treated, it must be distributed efficiently to various usage points. Poorly designed piping leads to pressure drops and energy losses. Key design principles :

- Use looped networks: Looping the distribution lines balance pressure

and allows for maintenance without shutdowns.

- Correct pipe sizing: Size for peak demand, not average flow, to avoid

friction losses.

- Use corrosion-resistant materials: Aluminium, copper, or stainless

steel prevent internal corrosion and contamination.

- Install pressure monitors and drains: Regular monitoring helps detect

leaks and pressure drops; automatic drains remove accumulated moisture.

4. Compressed Air Usage: Eliminate Waste and Control Demand

Even the most efficient generation and distribution setup can be undermined by poor usage practices.

Recommendations :

- Avoid open blowing: Replace it with air nozzles or blow guns designed

for efficiency.

- Fix leaks proactively: A single 3 mm leak can cost hundreds of

thousands annually in energy waste,

- Implement demand control strategies: Use flow controllers and

pressure regulators to match supply with real-time demand.

- Train operators: Ensure personnel understand proper air use and

system limits.

Conclusion

Developing an efficient compressed air system is not about just one piece of equipment, it's about optimizing each stage of the compressed air system. This way, plant managers and engineers can significantly reduce energy costs, extend equipment life, and improve production reliability.

Need help evaluation or upgrading your system?

Contact our engineering team for a comprehensive compressed air audit and customized efficiency solutions.